Introduction

AWR28HPC alloy wheel repair machine is smart diamond cutting wheel repair lathe which uses integrative touch screen PC controller, automatic detection system, integrative optimization software. It can repair wheels up to 28inch. The entire operation process only requires four steps: hub installation, wheel hub curve detection, curve optimization, and cutting to complete the repair. The machine operation is very simple, saving time and effort.

Specifications

◉Maximum clamping wheel size: 28inch

◉Maximum diameter with tire on: 770mm

◉X-axis drive motor torque: 6NM

◉Z-axis drive motor torque: 10NM

◉Motor power: 7.5KW

◉Spindle speed: 50-2000rpm

◉Chuck Diameter/Number of Jaws: 320mm / 3 jaws

◉Tool changer: 4 Station tool changer

◉X/Z feed accuracy: 0.001mm

◉Wheel detection method: Ruby probe detection system (optional laser detection system)

◉Detection accuracy Ruby probe detection: 0.001mm

◉Device Voltage / Frequency: 380V 3ph / 50HZ

◉Customization for different voltages: Support

◉Net weight / Gross Weight: 2000KG / 2200KG

◉Machine size: 2140 × 1600 × 1860mm

Features

◉Restores diamond cut alloy wheels < 28"

◉Integrative digital optimization software

◉17" Touch screen controller

◉Wheel profile storage - wheel library function

◉Automated self-plotting probe

◉Automatic electronic pump lubrication

◉X & Z axis servo motors - controlled cut

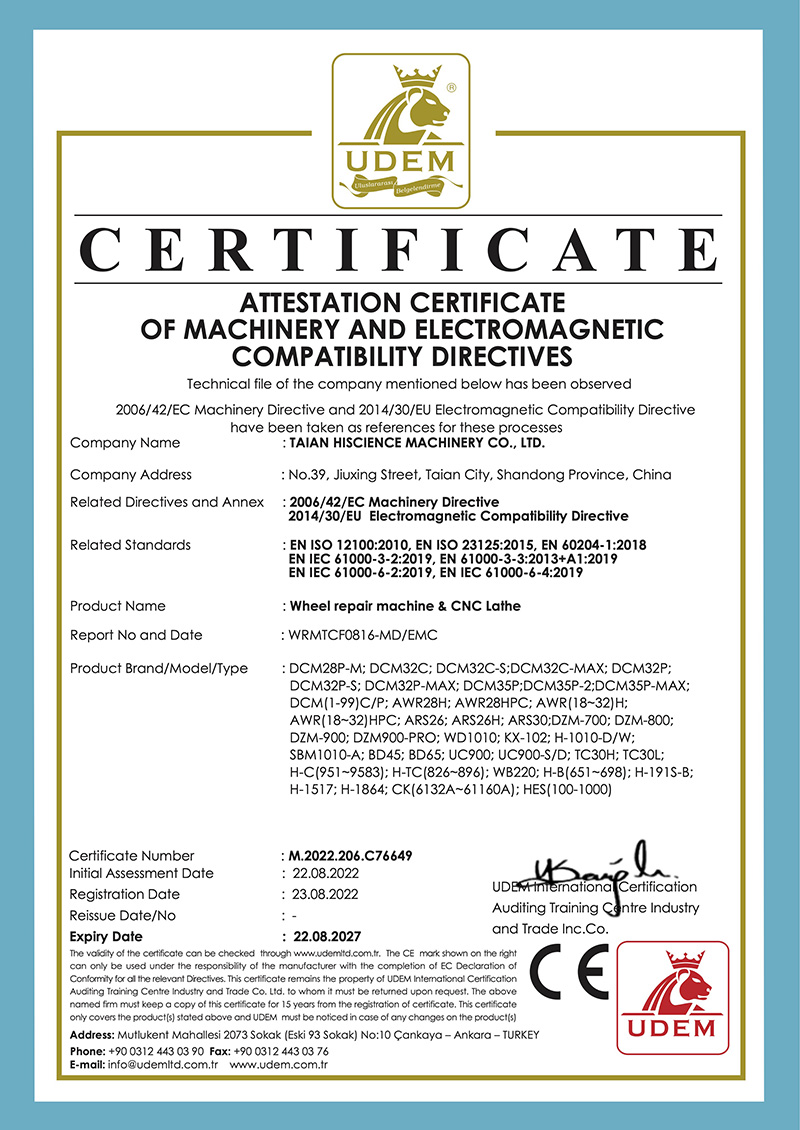

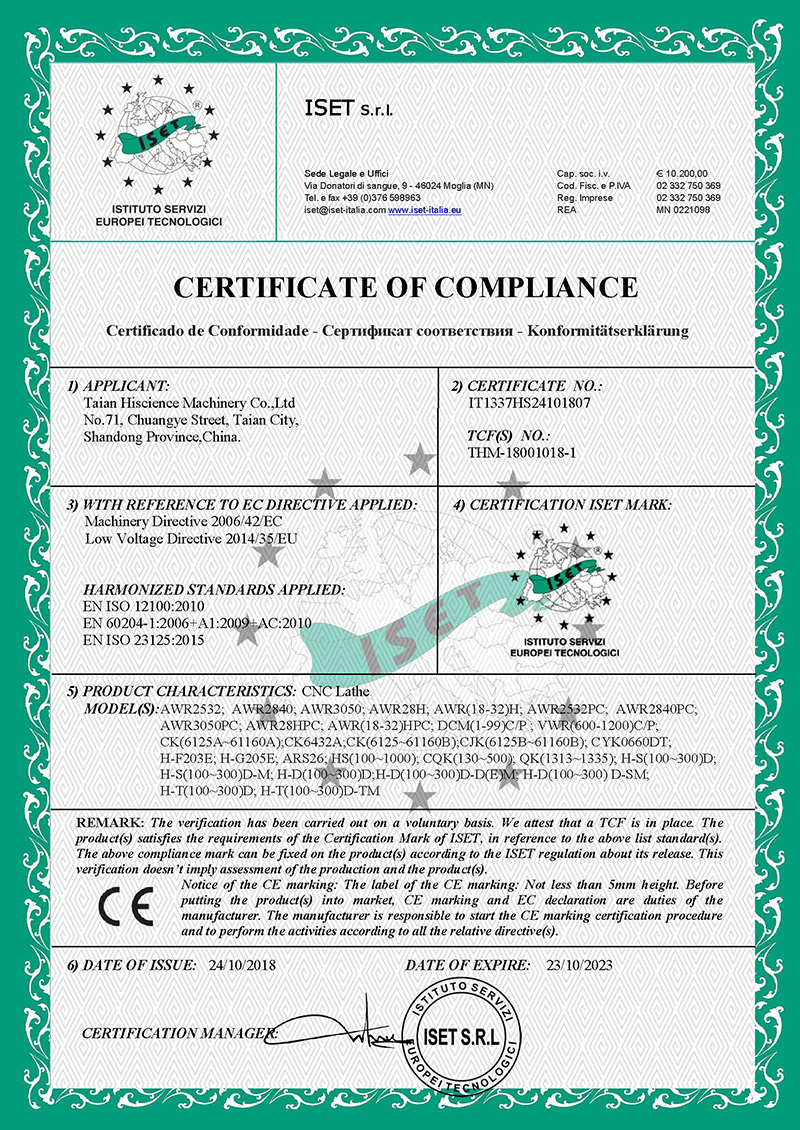

Certificate

CE

CE

Contact Us Today