Introduction

Sand blasting machine adopts suction sandblasting, which uses compressed air to flow in the spray gun at high speed to form a negative pressure to produce an ejection effect. The cyclone separator is installed. The abrasive in the storage tank is sucked into the spray gun through the hose and then follows the compressed air (flow from the nozzle at high speed) Sprayed onto the surface of the work piece to achieve the purpose of sandblasting.

Specifications

◉Cabin size: 1000 x 1000 x 765 mm

◉Outside size: 1070 x 1440 x 1700 mm

◉Front door size: 600 x 330 mm (width and height)

◉Right door size: 790 x 730 mm(width and height)

◉Number of guns: 1 (aluminum alloy with boron carbide nozzle)

◉Separator motor: 1 KW

◉Max loading: 50-100kg

◉Lighting: 18w fluorescent

◉Compressed air supply: Dry and clean compressed air with pressure

◉Air pressure requirements: 6-8 bar(kg/cm²)

◉Air flow requirements: 0.5-1.2m³/min(1 cubic)

◉Voltage: 220V / Single phase

Features

◉Novel design, convenient operation, saving floor space, equipped with environmental protection dust removal device, eliminating environmental pollution

◉This machine is designed for automatic sand return, which can recycle sand materials, reduce sand material consumption and save product cost

◉The machine has low noise, good sealing, no leakage or flying sand when working

◉Adopt pressure regulating separation device to precisely adjust the pressure, suitable for product blasting with higher product quality requirements

◉Pneumatic dust removal device is used. After sandblasting, just press the dust removal switch to clean the dust, which is convenient and labor-saving

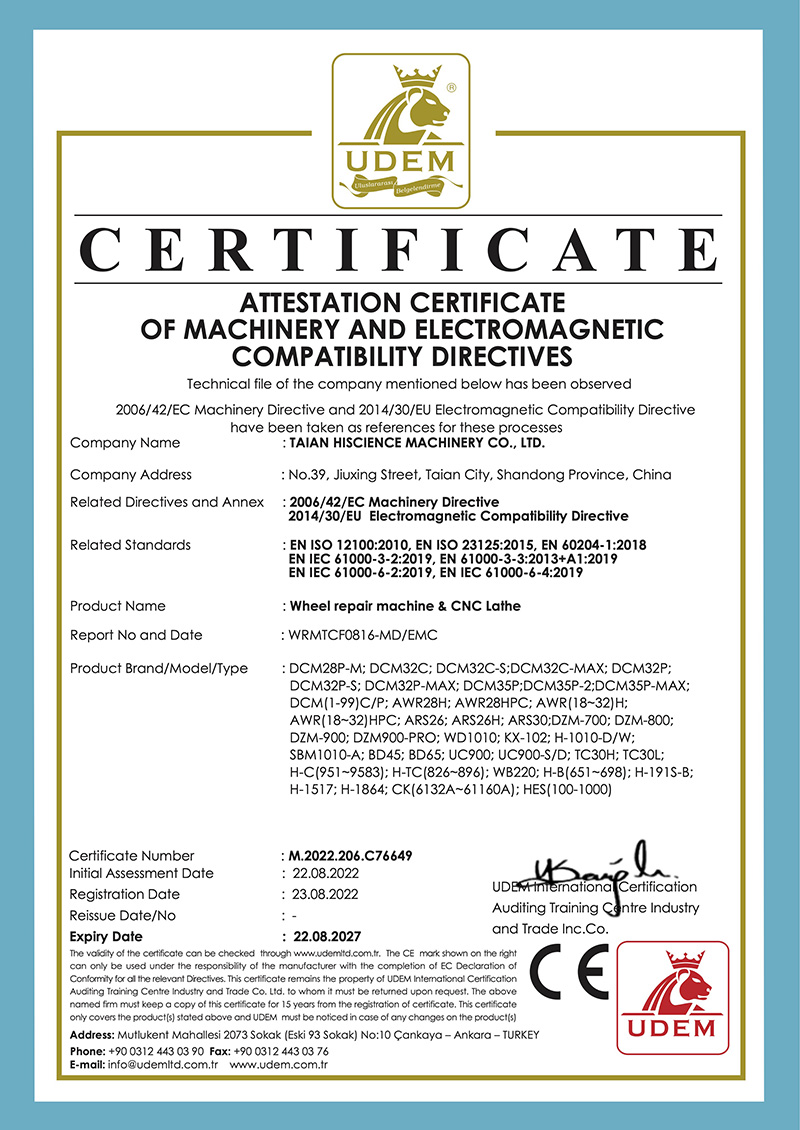

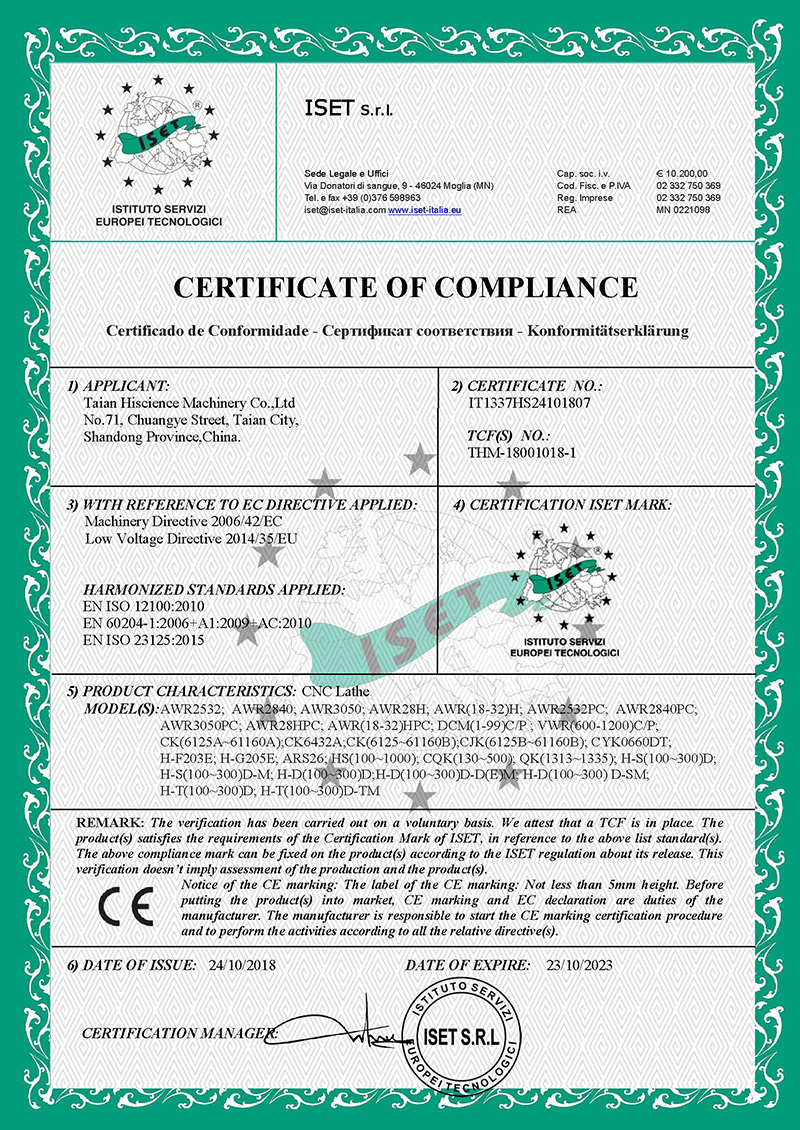

Certificate

CE

CE

Contact Us Today

Sand Blasting Machine