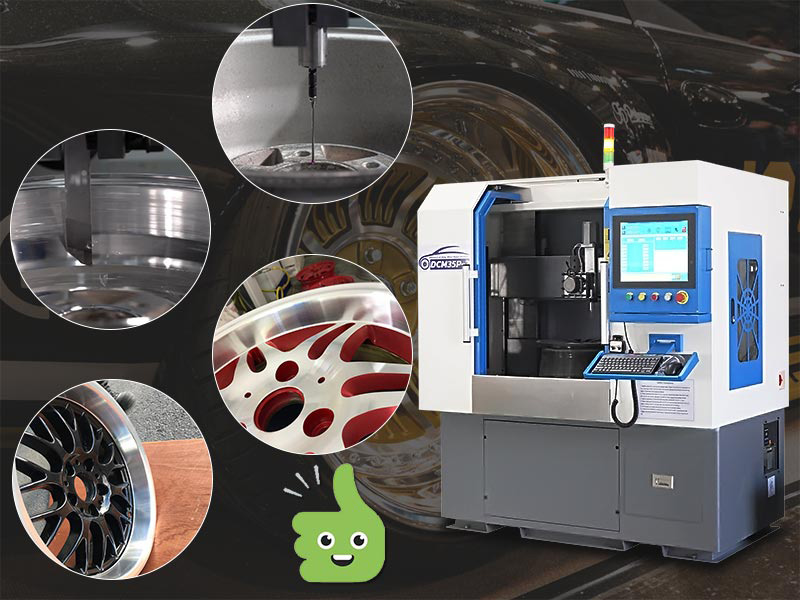

There are all kinds of wheels in the market. Before our customer buying a wheel repair machine or during the use of the wheel repair lathe, they often ask whether our wheel repair machine can be repaired or how to repair the deep dish wheels. I have a customer who is from Cyprus, he is very satisfied about the performance of our wheel repair machine DCM35P-2. But he want to figure out a question before place the order. That is can our wheel repair machine DCM35P-2 to repair deep dish wheels and back of wheels?

To prove to him that our wheel repair machine has no problem to repair deep dish wheels, we take a video call with him and show him why our machine can do this work. In practical applications, the handling of the more complex alloy wheel surface and wheel edge is more able to test the function of the detection system. The ruby collection point is the same as the R tool cutting trajectory, which is closest to the true curve of the wheel. The signal triggered by the ruby probe detection system is multi-dimensional, and the 3mm ruby diameter can suit the detection of different shapes of alloy wheels. Therefore, there is no doubt that the ruby probe system is no problem to perform a more perfect detection of complex wheel surface, more difficult wheel out edge and deep dish wheels. The length of longer ruby probe is 60mm. If the vertical depth of the rim relative to the spokes is less than 60mm, the normal detection of the wheel repair machine detection system can be guaranteed, and then the perfect repair can be made by selecting the appropriate diamond cutter. We also prepare longer ruby probe and probe extension for our customers. If your wheel depth is particularly deep, you can add more probe extensions to achieve detection.

We also have the longer diamond cutters for you to cut deep dish wheels. The length of longer diamond cutter is 280mm. The diamond cutter with 3mm diameter spherical can perfectly repair the vertical plane of the wheel.

We also equipped with optimized software, by optimizing the curve through optimization software, the cutting trajectory of the tool can be very close to the true curve of the wheel end face, without any impact on the safety of the wheel. By setting the feed parameters of the tool, the surface of the wheel can achieve various customer-required effects such as big line effect rainbow line effect and mirror effect.

After the video call, this customer has not worried about the function. For different wheel, if need different wheel lathe configuration, HIENCE wheel repair machine can meet your requirements, so as to ensure that you can repair most of the wheel.

Keywords: wheel repair machine

Originally published 11 May 2021, updated 11 May 2021.